A cold working process for sheet metal (usually less than 6mm), including cutting, punching/cutting/compounding, folding, riveting, splicing, forming, etc.

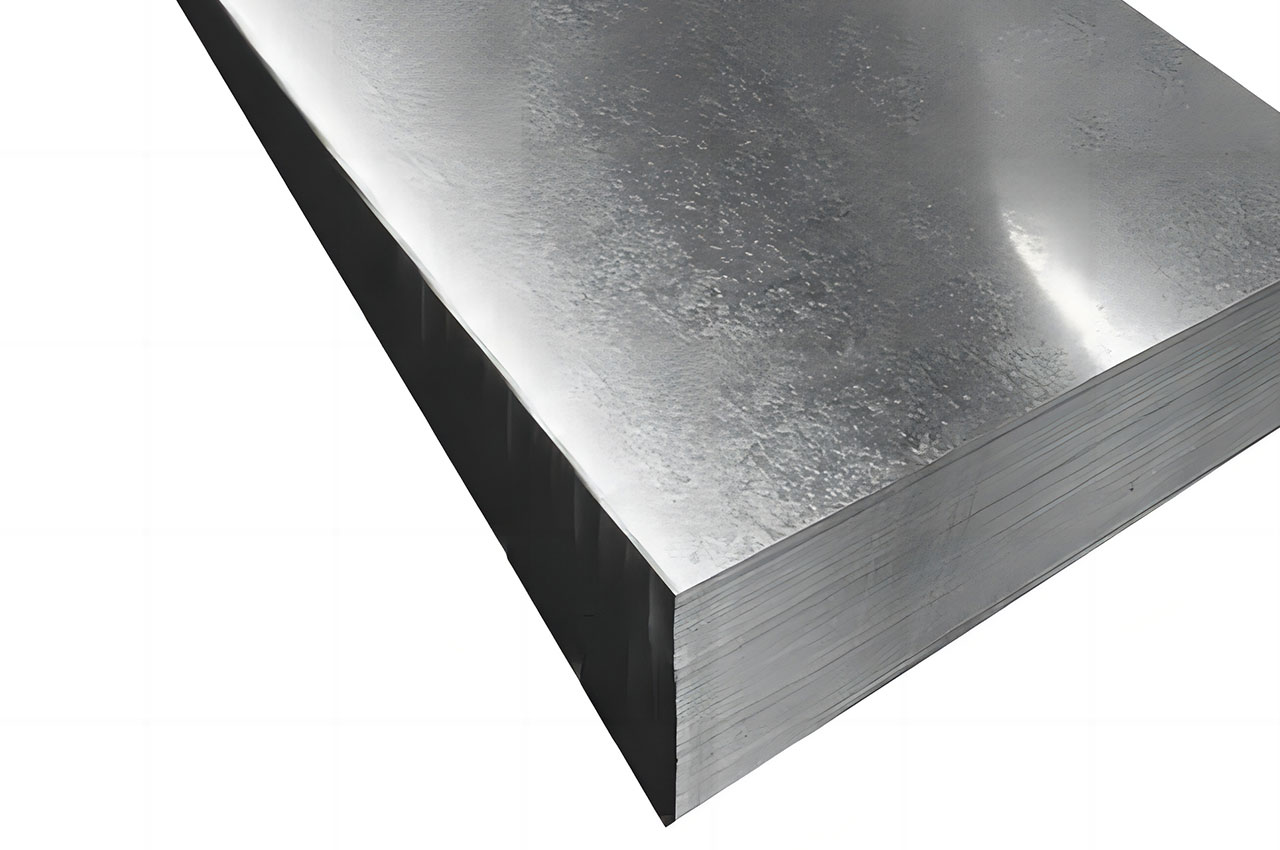

It has good corrosion resistance and strength, and is often used in occasions with high anti-rust requirements, such as kitchen equipment, medical equipment and so on.

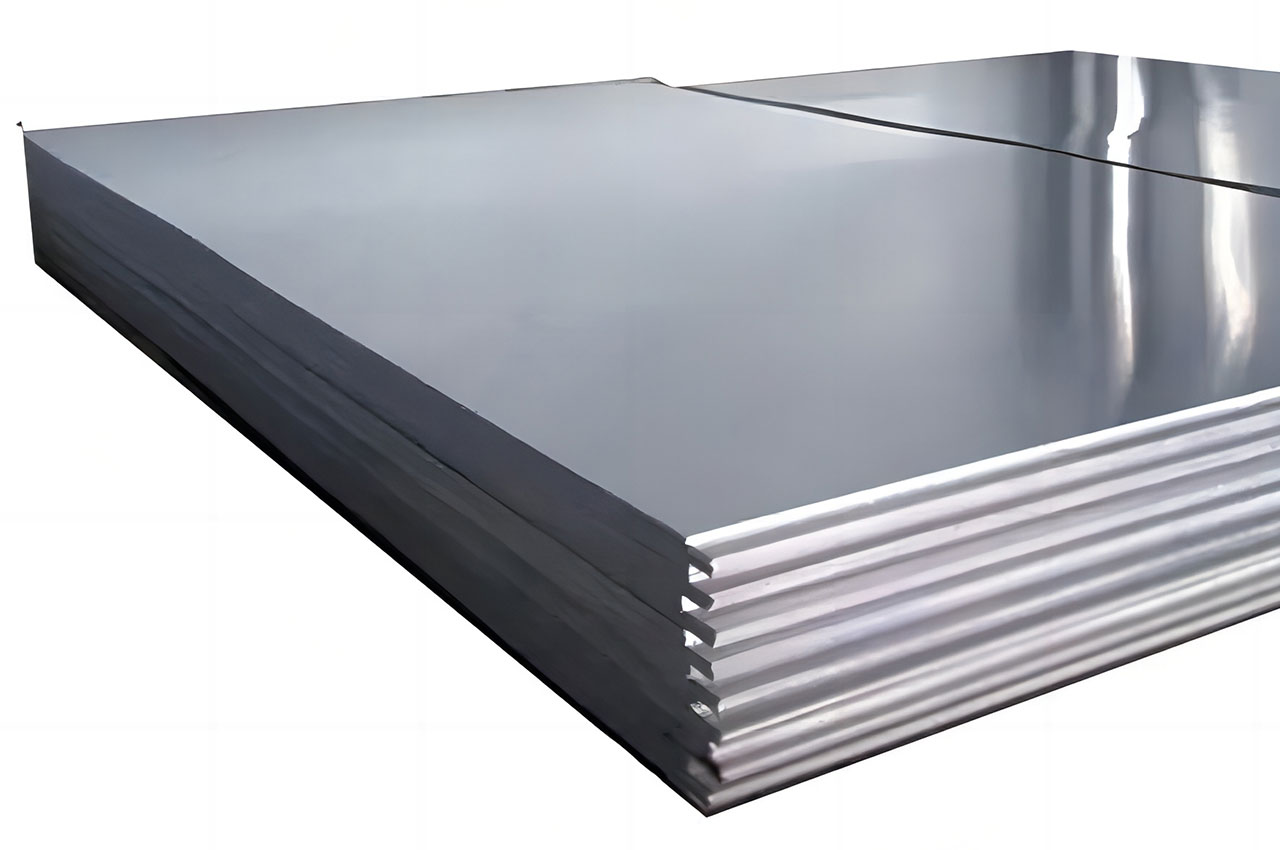

Good surface quality, high dimensional accuracy, widely used in all kinds of electrical appliances, chassis cabinets and other products.

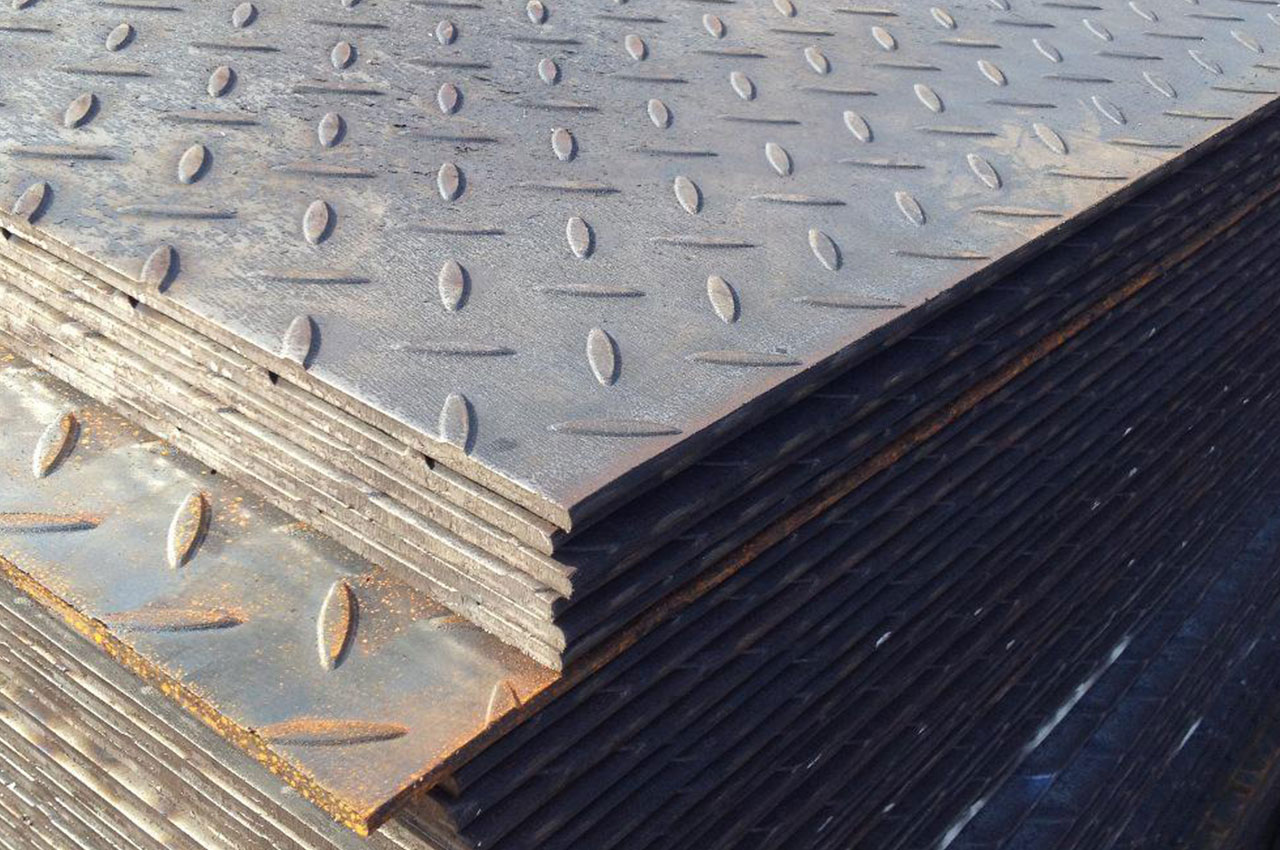

High strength, relatively low price, suitable for the surface requirements are not high but need high strength structural parts.

Excellent electrical and thermal conductivity, often used in electrical equipment and heat dissipation components.

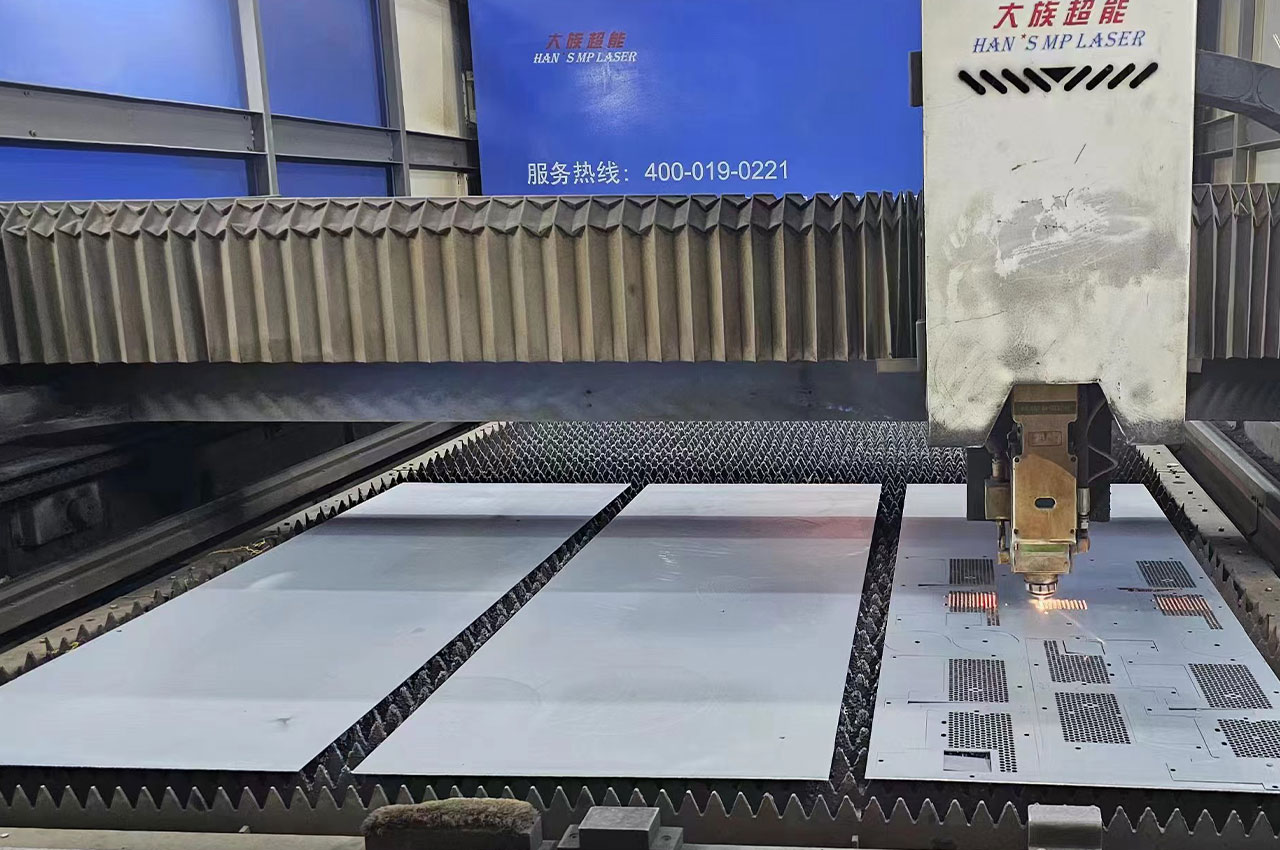

┊ Cutting: cutting machine or laser cutting machine, plasma cutting machine and other high-precision equipment.

┊ Stamping: through the punching press and mold, out of the plate holes, grooves, convex hull and other shapes.

┊ Bending: The use of bending machine to fold the plate into a certain Angle and shape to form a three-dimensional structure of the sheet metal.

┊ Welding: For the parts that need to be spliced, welding methods such as arc welding, argon arc welding, gas welding are used to connect.

┊ Surface treatment: including deburring, grinding, polishing, painting, electroplating, oxidation and other treatments to enhance rust prevention and beauty.

┊ Assembly: The individual sheet metal parts are assembled together to form a complete product.

┊ Quality inspection: Size measurement, appearance inspection and strength test of the completed sheet metal parts to ensure that they meet the quality standards.

┊ Material diversity: can handle all kinds of metal plates, such as stainless steel, aluminum, copper, cold rolled plate, etc.

┊ Strong shape plasticity: through cutting, bending, stamping, drawing and other processes to process the plate into a variety of complex shapes and structures.

┊ Controllable accuracy: According to different processing equipment and technology, high dimensional accuracy and shape accuracy can be achieved.

┊ High customizability: Can be customized according to the specific needs of customers.

┊ Efficient mass production: suitable for large-scale mass production, high production efficiency.

┊ Relatively low cost: At a certain scale, the cost is more economical than other manufacturing processes.

┊ Flexible surface treatment: It can be painted, electroplated, oxidized and other surface treatments to meet different appearance and protection requirements.