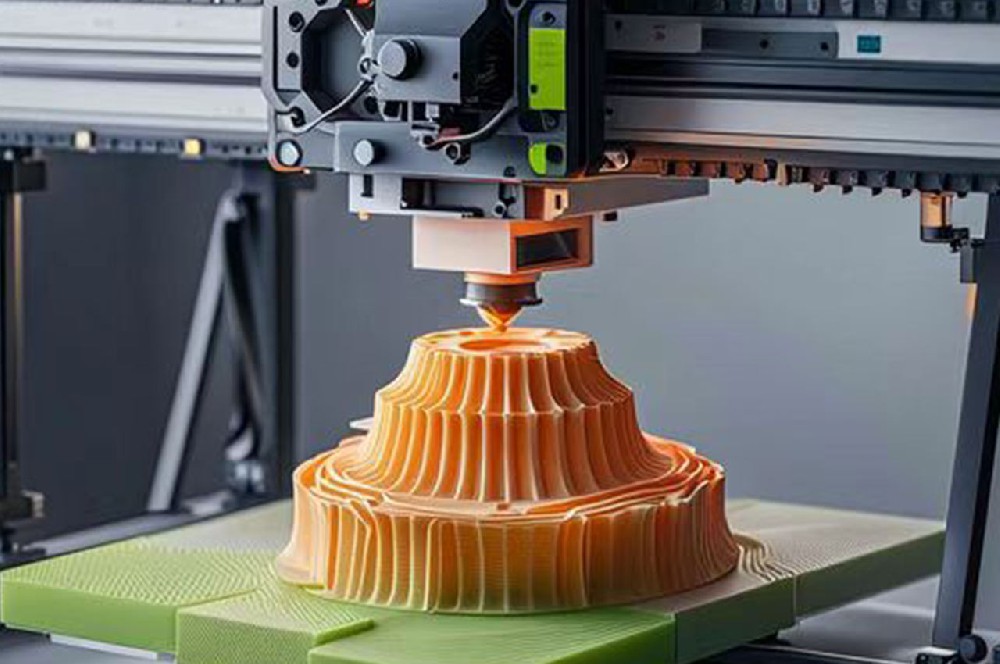

3D printing is a rapid prototyping technology that uses powdered metal, plastic or other adhesive materials to create objects by printing them layer by layer, based on digital model files. The basic principle is to cut the three-dimensional model into a series of sheets, and then overlay these sheets layer by layer through the 3D printing equipment, and finally form a three-dimensional solid part.

Such as ABS, PA, PC, PPSF, PEEK and so on. These materials have good hot melt, impact strength and mechanical properties and are suitable for a variety of 3D printing applications.

Such as titanium alloy, aluminum alloy, stainless steel and so on. 3D printing of metal materials usually requires the use of special techniques such as selective laser melting (SLM) or electron beam melting (EBM).

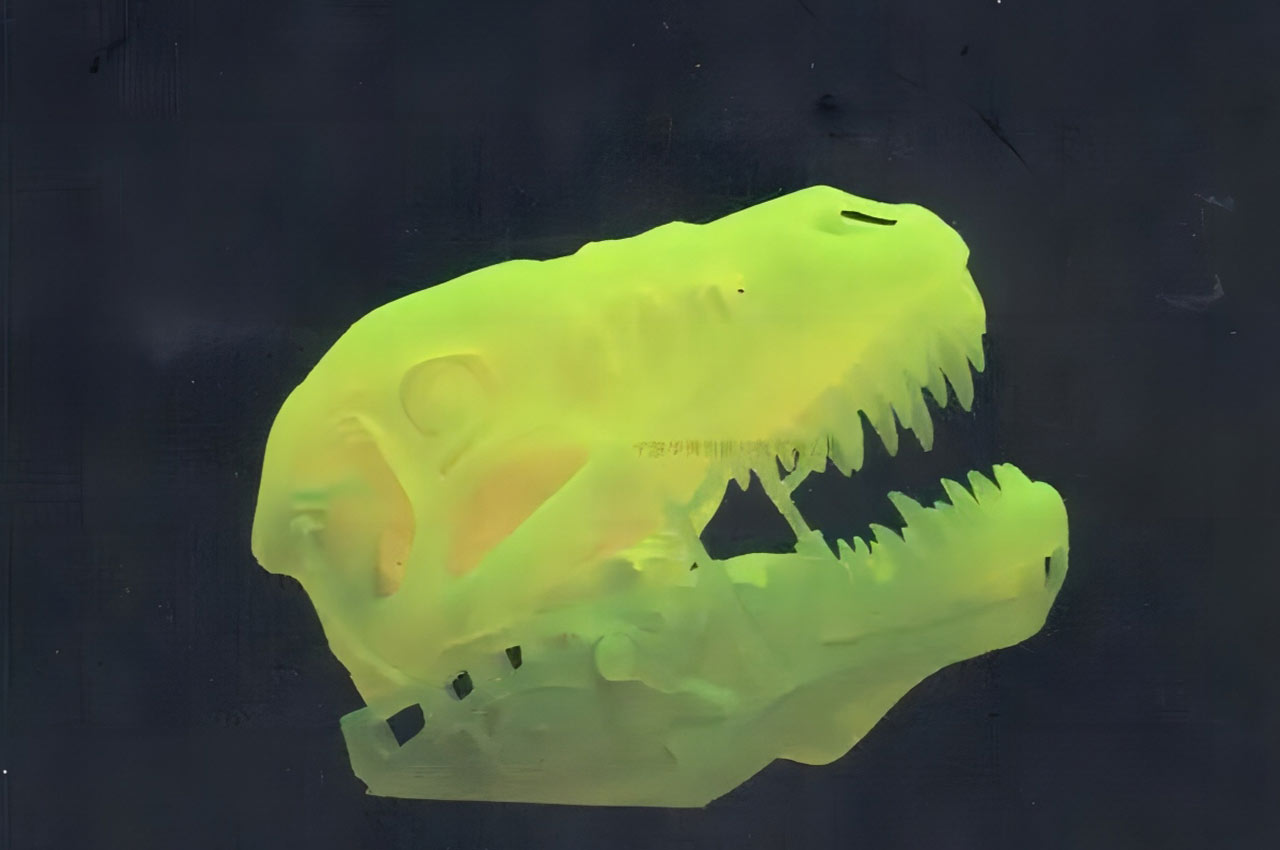

Such as alumina, zirconia, silicon nitride and so on. 3D printing of ceramic materials can produce parts with high precision and high hardness, but usually requires post-processing, such as sintering.

Such as carbon fiber reinforced composite materials, glass fiber reinforced composite materials, etc. These materials combine the advantages of two or more materials with high strength and stiffness.

┊ Modeling: Create 3D models using computer-aided design (CAD) software or other modeling tools.

┊ Slicing: Convert a 3D model to STL format and use slicing software to cut it into a series of sheets while setting print parameters such as temperature, speed, fill density, and more.

┊ Printing: Slice data is transmitted to a 3D printer, which prints layer by layer according to parameters set, depositing the material onto the print bed to form a three-dimensional object.

┊ Post-processing: After printing is complete, some post-processing work needs to be done, such as removal of support structures, sanding, polishing, coloring, etc., in order to obtain the final product.

┊ Rapid prototyping: Design concepts can be quickly translated into physical objects, greatly shortening the product development cycle and reducing production costs.

┊ Customized production: With high production flexibility, products can be customized to meet the demands of an increasingly diverse market.

┊ High utilization of materials: Using the layer-by-layer stacking method, only the necessary materials are used, saving resources and reducing environmental pollution.

┊ High degree of design freedom: free from the constraints of traditional manufacturing processes, it is able to print out complex geometric structures and interior Spaces, providing designers with more creative space.

┊ Multiple materials selection: Support the use of a variety of materials, such as plastics, metals, ceramics, biological materials, etc., and have a wide range of application prospects in various fields.