Compound mold is a processing method used to manufacture injection molds, which is copied and processed on the basis of the prototype mold to obtain the final injection mold. The remolding process can help manufacturers quickly produce high-quality injection molds. Compared with traditional hand-made molds, the remolding process has the advantages of improving production efficiency, maintaining mold accuracy and reducing costs.

It has good flexibility, heat and corrosion resistance, and can accurately reproduce the details of the prototype.

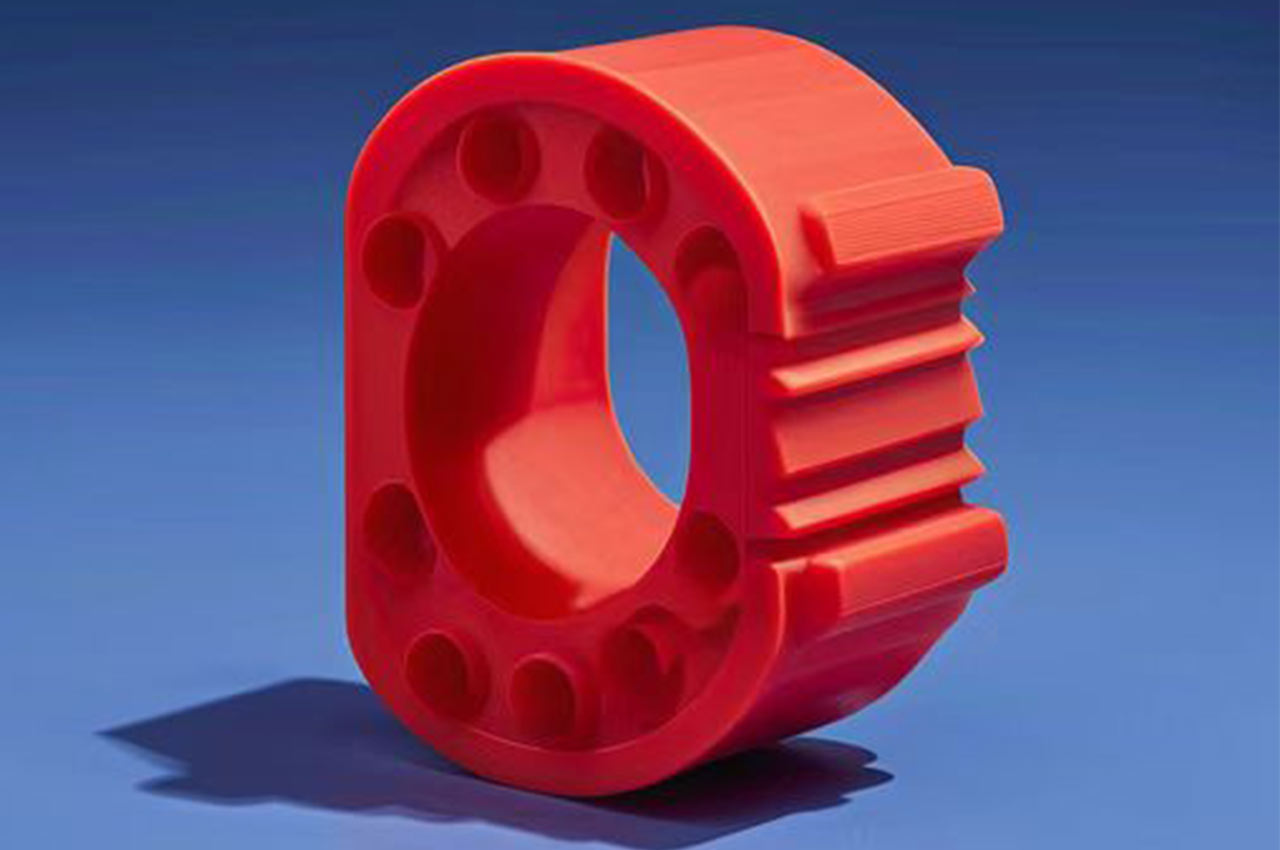

┊ Prototype mold making: Make a prototype mold based on the design requirements of your product. Prototype molds can be manufactured by 3D printing, CNC machining and other methods.

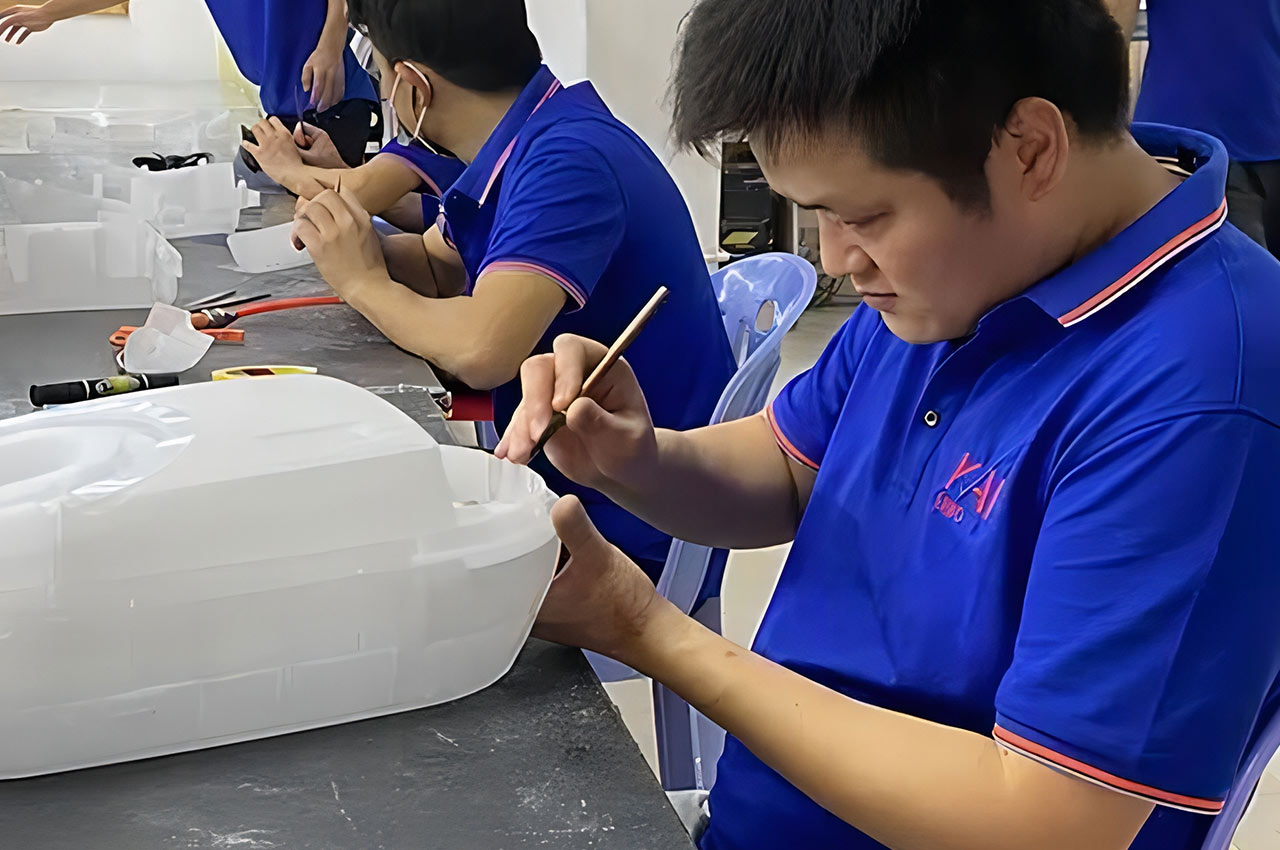

┊ Mold surface treatment: The prototype mold is surface treated for subsequent replication and processing. This includes steps such as cleaning, polishing, applying separation agent, etc.

┊ Compound mold material selection: Select the right compound mold material based on the materials and requirements of the prototype mold. Commonly used compound materials include silicone, polyurethane and so on.

┊ Compound mold: Pour the compound mold material into the prototype mold and remove it after curing. This results in a complex mold with the same shape as the prototype mold.

┊ Mold processing: Processing of the complex mold, including finishing, hole machining, wire cutting and other steps to obtain the final injection mold.

┊ Relatively low cost: Compound molds are economical to produce in small batches compared to open molds for injection production.

┊ Short production cycle: The ability to produce prototypes or small batches quickly reduces delivery times.

┊ High reproduction accuracy: The detail and precision of the prototype can be duplicated quite well.

┊ Suitable for complex shapes: Compound molds have advantages for products with complex structures that are difficult to manufacture by traditional processing methods.

┊ Selection of materials: Common replica materials include silica gel, resin, etc., and suitable materials can be selected based on product requirements.

┊ Easy to modify and adjust: Based on the copied prototype, it is easy to make local modifications and adjustments to meet specific requirements.

┊ Small batch production: Suitable for small batch production of up to a few hundred pieces, meeting the market demand for rapid product testing and initial delivery.