Die casting is a kind of metal casting process, which is to fill the mold of molten alloy under high pressure and high speed, and solidify under high pressure.

It has good fluidity, corrosion resistance and mechanical properties, and is widely used in auto parts and electronic equipment shells.

Light weight, high strength, in aerospace, automotive and other fields have applications.

It has good electrical and thermal conductivity, but the die casting is relatively difficult and the application is relatively few.

Low melting point, good fluidity, often used to manufacture small, complex parts, such as toys, furniture hardware and so on.

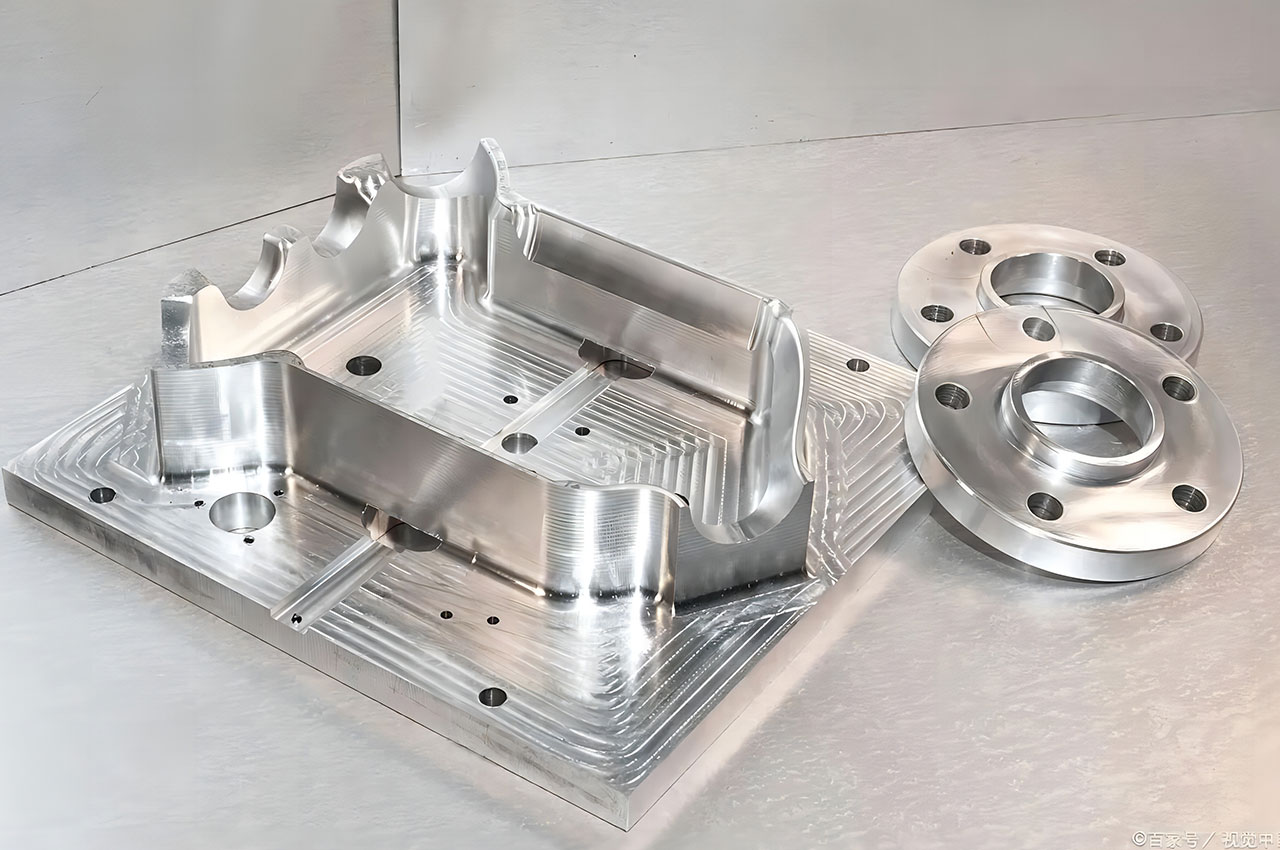

┊ Mold design: Design the right mold based on the shape and size of the product.

┊ Raw material preparation: Metal materials are mixed in a certain proportion and pre-treated to ensure the quality and properties of the material.

┊ Smelting metal: Heat the raw material to the melting point and maintain a temperature that brings it into a molten state.

┊ Injection mold: Molten metal is injected into a mold, where high pressure fills the entire mold cavity and is held for a certain amount of time to ensure that the metal is fully solidified.

┊ Cooling curing: The metal to be injected gradually cools in the mold, solidifying and forming.

┊ Stripping: Perform a stripping operation to remove solidified metal pieces from the mold.

┊ Post-treatment: Post-treatment, including removal of residual materials, finishing of surfaces, heat treatment, etc., to improve the quality and performance of the product.

┊ High Pressure filling: In the die casting process, metal is injected into the mold cavity under high pressure to obtain a high precision, high quality casting.

┊ High-speed forming: The filling speed of die casting is very fast, and the molding process of the casting can be completed in a short time, improving production efficiency.

┊ High precision: Die casting can produce castings with complex shapes, high dimensional accuracy and good surface quality.

┊ Suitable for high volume production: Because die casting molds can be reused, they are suitable for high volume production and reduce costs.

┊ A wide variety of materials are available: A wide variety of metal materials can be used for die casting, such as aluminum, zinc, magnesium, copper, etc.

┊ Die casting also has some limitations, such as high mold cost and not suitable for small batch production.