Stamping is a metal processing method that applies external forces to metal sheets, strips, pipes and profiles through molds to produce plastic deformation or separation, so as to obtain the required shape and size of the workpiece.

It has good plasticity and stampability, relatively low price, and is widely used in all kinds of stamping parts.

Light weight, good conductivity, good corrosion resistance, often used in electronics, aerospace and other fields of stamping parts.

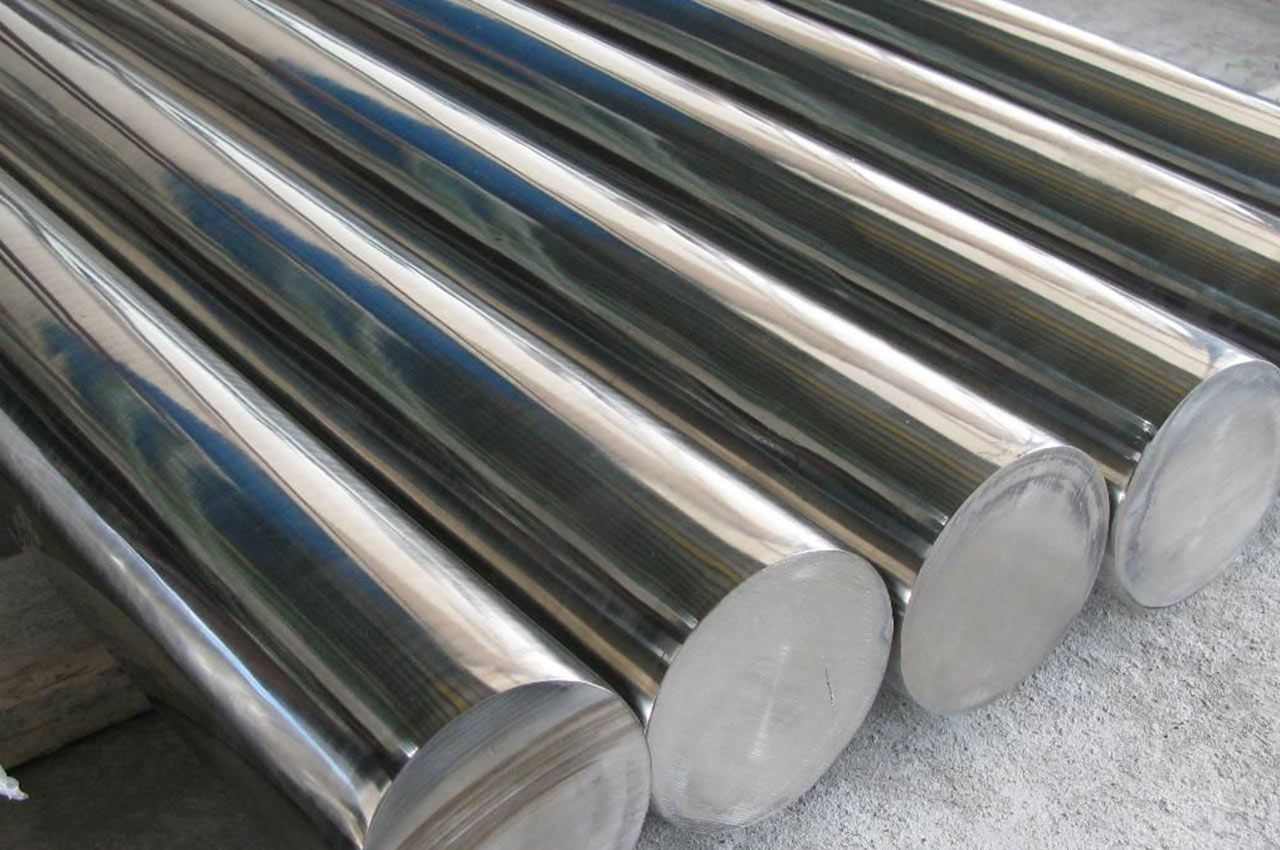

It has good corrosion resistance and strength, and is often used in the manufacture of stamped parts with corrosion resistance requirements.

High strength, good corrosion resistance, but the price is high, often used in aerospace and other high-end fields.

┊ Raw material preparation: Select the appropriate plate, such as steel plate, aluminum plate, etc., and cut and pre-treat according to the mold size.

┊ Stamping operation: The plate is placed on the table of the punching machine, and the pressure is applied to the plate through the up and down movement of the mold to make it undergo plastic deformation and form the required parts.

┊ Separation and unloading: After the stamping is completed, the workpiece is separated from the waste, and the stamping part is removed from the die through the unloading device.

┊ Quality inspection: The dimensional accuracy, shape accuracy, surface quality and other aspects of the stamping parts are tested to ensure that they meet the design requirements.

┊ Follow-up treatment: According to needs, the stamping parts are deburring, cleaning, surface treatment (such as electroplating, painting, etc.) and other follow-up treatment to improve its performance and appearance.

┊ Efficiency: The pressing process is usually completed in a short time and is productive, making it suitable for large-scale series production.

┊ Precision: The ability to obtain parts with high dimensional accuracy, complex shapes, and good consistency.

┊ High utilization of materials: With reasonable layout design, raw materials can be maximized and waste generation reduced.

┊ Low cost: Due to high production efficiency and large batches, the cost spread over each part is relatively low.

┊ Can process a wide variety of materials: suitable for a variety of metal sheets, such as steel, aluminum, copper, etc.

┊ Good strength properties: The cold working hardening effect of materials during the stamping process can increase the strength and hardness of parts.

┊ Easy to operate: The operation of stamping equipment is relatively simple and easy to automate production.