Chip machining is a machining method in which excess material is removed from the workpiece by cutting tools to obtain the desired shape, size and surface quality.

Steel (including carbon steel, alloy steel), cast iron, copper, aluminum, zinc, titanium and its alloys, etc.

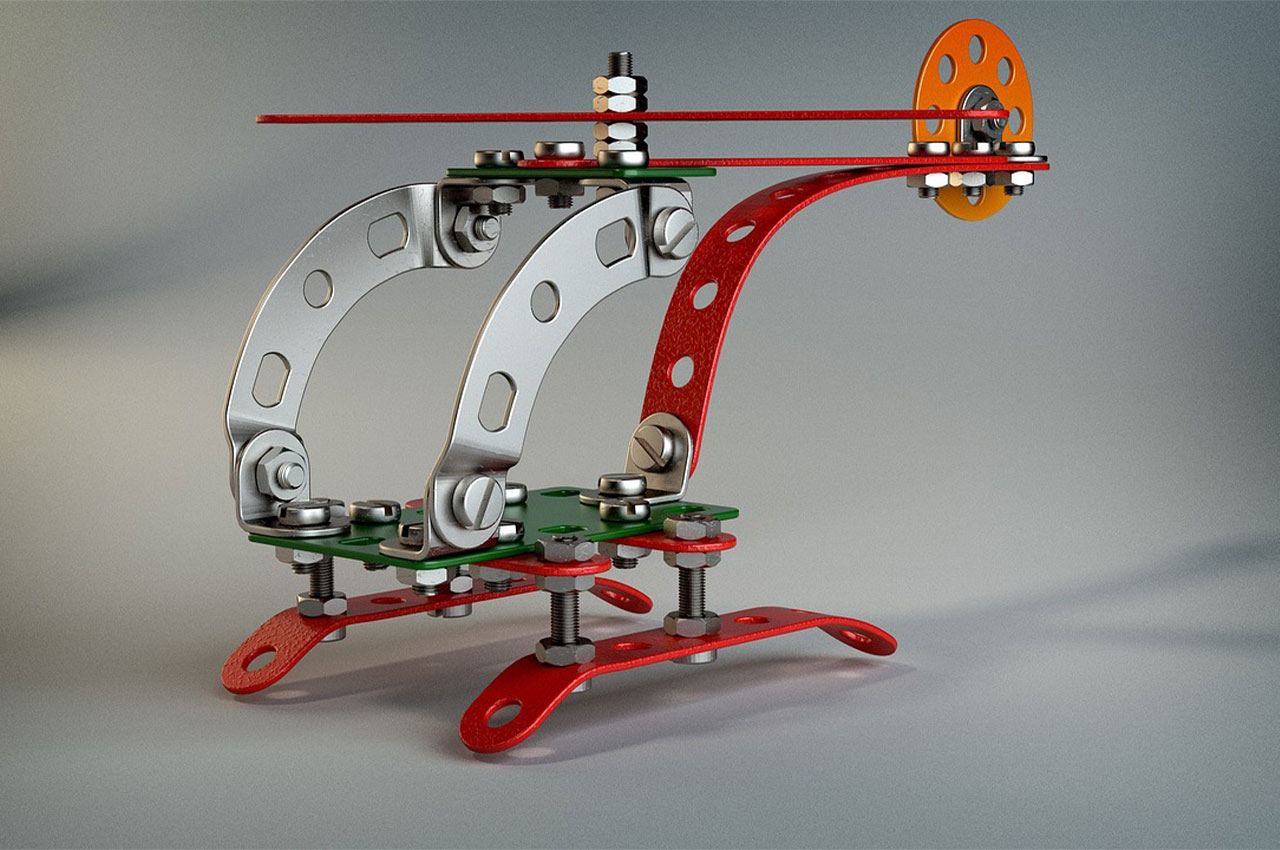

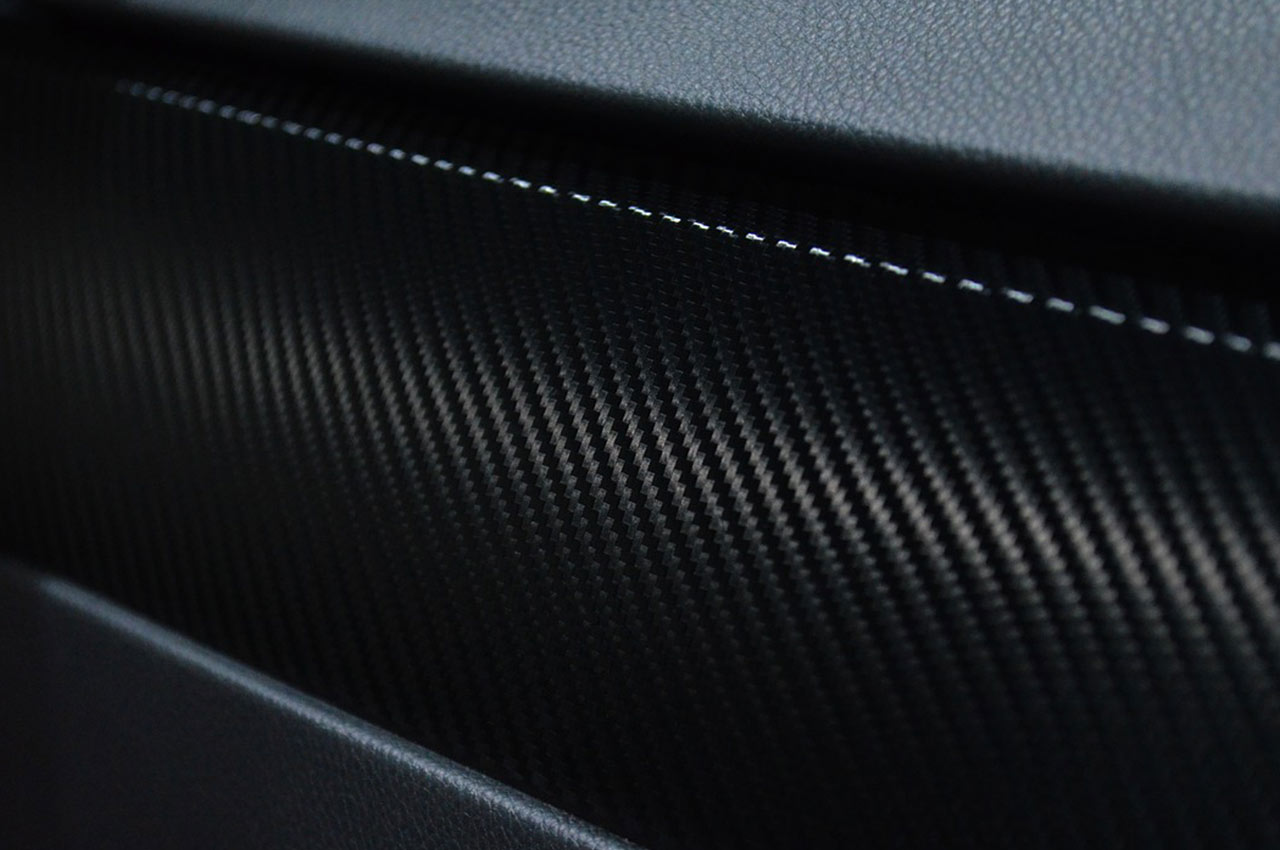

Such as carbon fiber reinforced composite materials, glass fiber reinforced composite materials, etc.

┊ Workpiece clamping: Secure the workpiece to be processed in the workbench or fixture of the machine tool to ensure that it remains stable during processing.

┊ Tool selection: Depending on the material, shape, size and machining requirements of the workpiece, choose the right tools, such as turning tools, milling tools, drills, etc.

┊ Machine adjustment: Make the necessary adjustments to the machine, including the installation of the tool, the setting of parameters such as cutting speed, feed speed, depth of cutting, etc.

┊ Cutting process: Start the machine and the tool makes a cutting motion on the workpiece, cutting away excess material. During the cutting process, chips are produced.

┊ Measurement and inspection: The size, shape and surface quality of the workpiece are measured and inspected using measuring tools to ensure compliance with requirements, either during processing or after processing is complete.

┊ Precision: High dimensional accuracy and surface roughness requirements are achievable.

┊ Complex shape: It can process a variety of parts with complex shapes, including flat, curved, spiral, etc.

┊ Materials are wide range: suitable for most engineering materials such as metals, plastics, ceramics, etc.

┊ Removal margin: Can effectively remove excess material from the blank and achieve the shape and size required by the design.

┊ Good reproducibility: under the same process conditions, the processing results have good consistency and reproducibility.

┊ Process flexibility: You can adapt to different processing needs by adjusting tools, cutting parameters, etc.

┊ Equipment diversity: There are a wide range of machine tools available - lathes, milling machines, drilling machines, grinders to meet different cutting tasks.