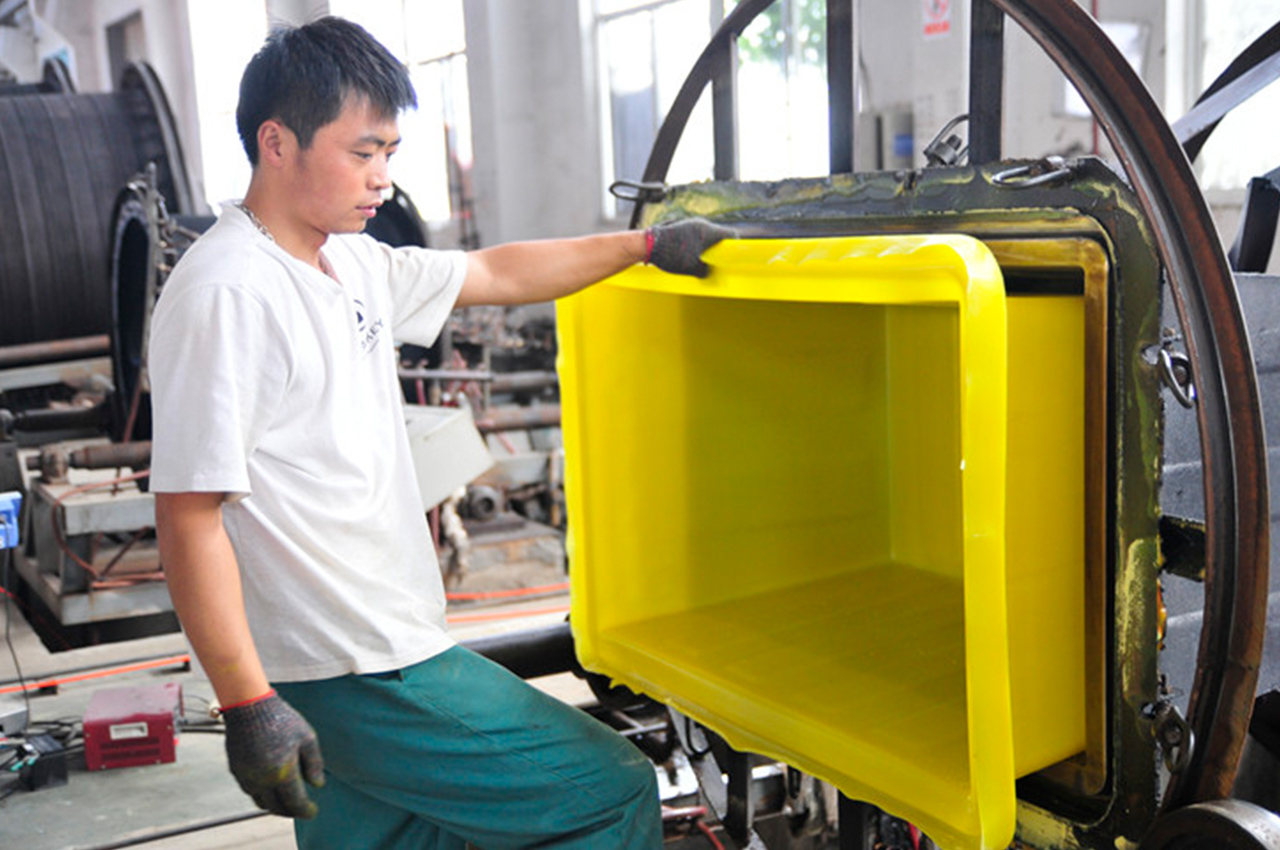

Rotomolding, also known as rotary molding, is a plastic molding process. It is the quantitative powder or liquid plastic raw materials into the mold, through the mold in the heating furnace along the two vertical axis continuous rotation and heating, the plastic raw materials in the mold under the action of gravity and heat energy, gradually uniform coating, melting adhere to the entire surface of the mold cavity, molding for the required shape, and then cooling, mold, finally obtained products.

┊ Material selection and feeding: According to the product needs to choose the appropriate plastic material, and feeding. ┊ Mold closure and installation: Close the mold and install it on the rotating frame of the rolling machine. ┊ Heating: The mold is rotated on one side of the rolling machine along two perpendicular axes, while the other side is heated in the heating furnace. Rotation makes the plastic raw material evenly distributed on the inner wall of the mold, and heating makes it melt. ┊ Cooling: After the heating is completed, the mold is removed from the heating furnace, and the plastic is cooled and solidified by natural cooling or forced cooling. ┊ Demoulding: Open the mold and take out the molded plastic product. ┊ Post-treatment: The product is trimmed, polished, drilled and other follow-up treatment to obtain the final product.

┊ Quality inspection: The appearance inspection, size measurement, performance testing of products, etc., to ensure that products meet quality standards.

┊ High design flexibility: Hollow products of almost any shape can be formed, not subject to the complexity of the structure and shape of the product.

┊ Mold cost is low: Molds are relatively simple, usually composed of two half molds, and the manufacturing cost is lower than that of processes such as injection molding, which is especially suitable for small batch production of products with complex shapes.

┊ Uniform and adjustable wall thickness: By adjusting heating and cooling times and rotation speed, it is easier to control the wall thickness of the product and make it evenly distributed.

┊ Suitable for large products: Capable of manufacturing very large hollow plastic products, such as large storage tanks, amusement facilities, etc.

┊ Products Good integrity: Rotundized products are formed in one, without seams, with good strength and sealing.

┊ A wide selection of materials: Most thermoplastics are suitable for rotundization processes.