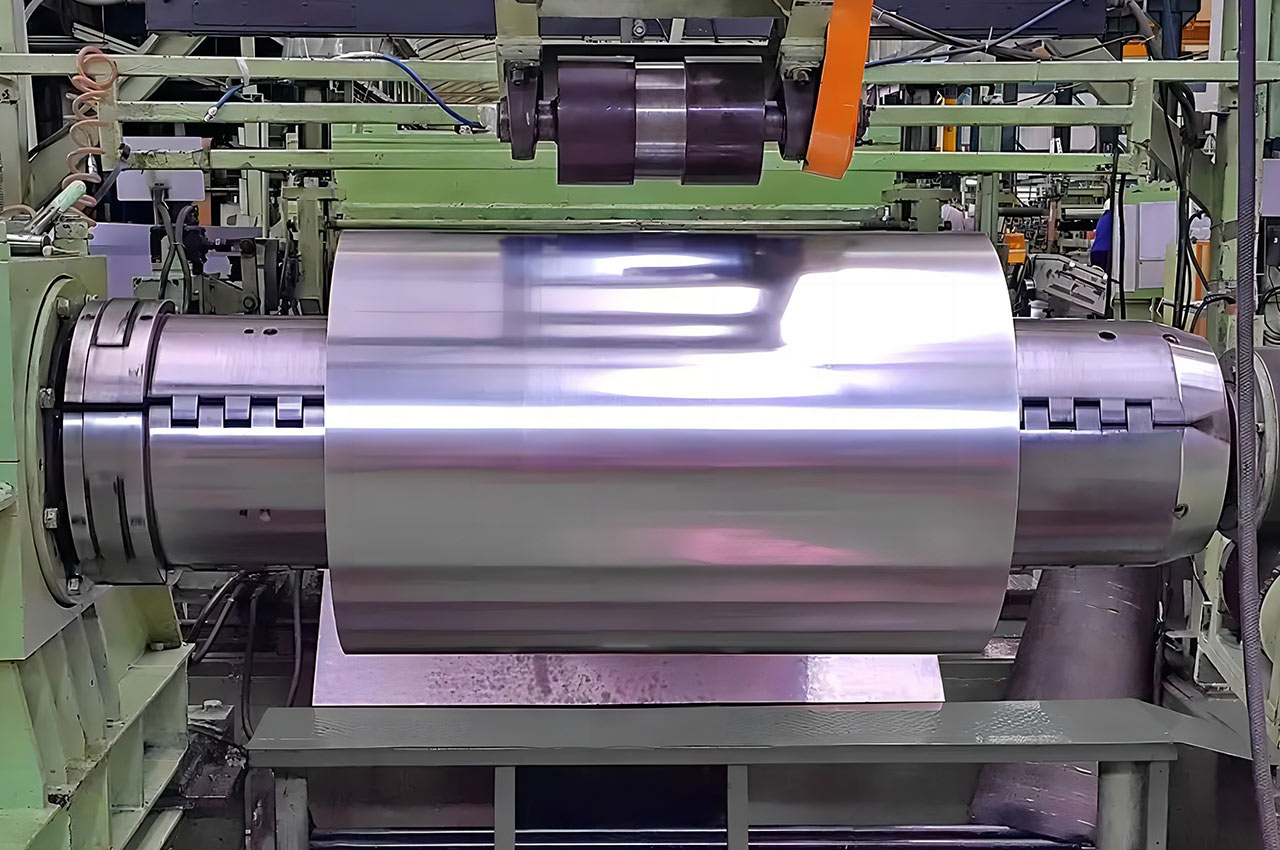

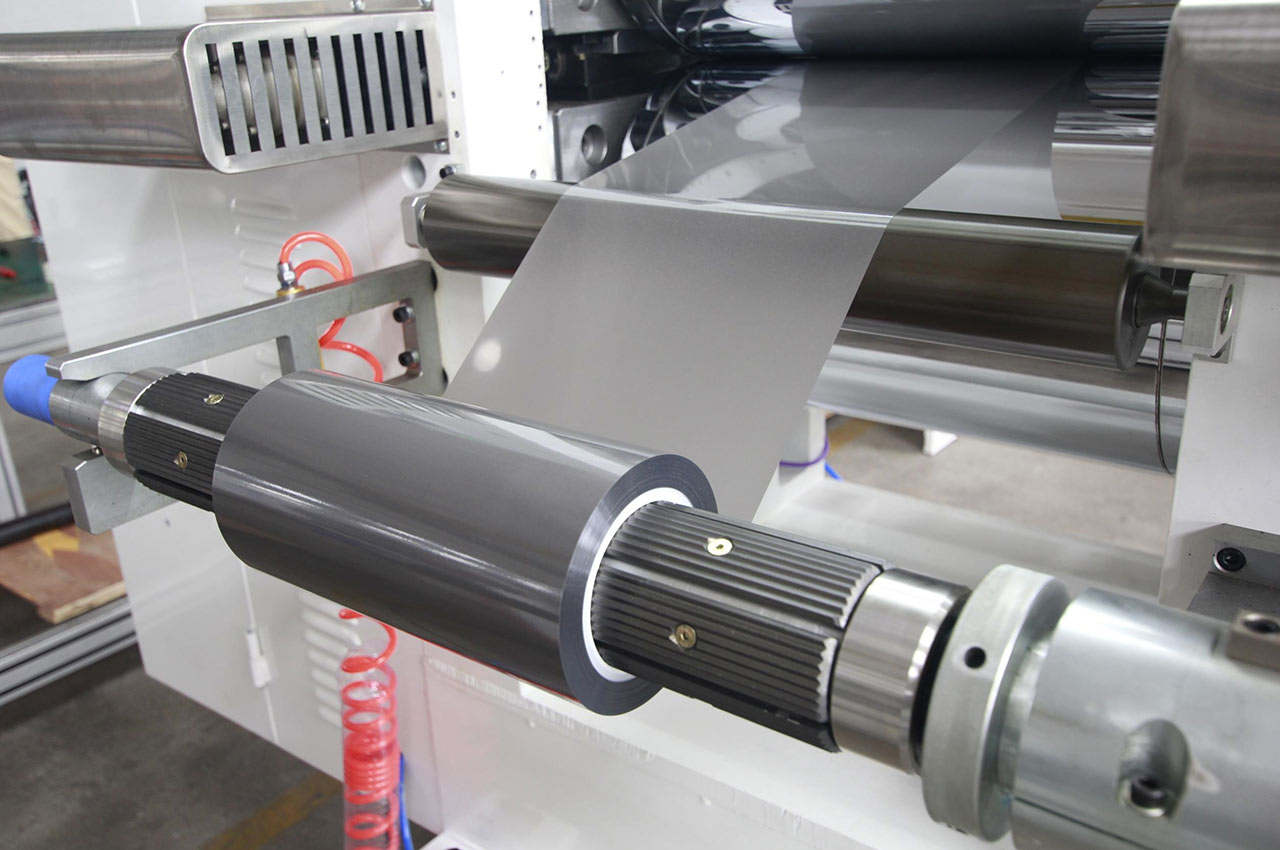

Calendering is a method of forming a continuous sheet product with a certain thickness and width through a series of parallel roll gaps that rotate opposite and gradually reduce the spacing, so that the thermoplastic has been plasticized.

During the calendering process, the material flows and deforms plastically under the pressure and friction of the roll, so as to achieve uniform thickness and good surface quality. Calendering is often used in the production of plastic films, sheets, artificial leather, coated fabrics and other products.

┊ Raw material preparation: Raw materials are dried, screened, proportioned and mixed to ensure uniformity.

┊ Plasticizing: The mixed raw materials are added to the mixer or the open mixer for heating and shearing, so that it is fully plasticized to form a material with certain plasticity.

┊ Feed: The plasticized material is transported to the feed end of the calender by conveyor belt or extruder.

┊ Lead off: The calendered sheet material is removed from the roll by the lead off device.

┊ Cooling styling: The removed material is quickly cooled through a cooling device, such as a cooling roller or water tank, to fix its shape and size.

┊ Trimming and coiling: Cutting off parts of the material with uneven edges and then winding them into rolls for storage and transportation.

┊ High production efficiency: Capable of continuous production, faster speed and suitable for mass production.

┊ Products are of good quality: products with uniform thickness and smooth, flat surfaces are obtained.

┊ Product width is large: A wider sheet or film can be produced.

┊ Products have higher accuracy: more precise control over thickness and size.

┊ Multilayer composite: The ability to stack layers of different materials or different properties together to form multilayer composites.

┊ Equipment investment is large: Equipment such as calenders are more complex and expensive.

┊ High requirements for raw materials: raw materials are required to have good plasticity and fluidity.

┊ Process adjustment is more complex: Once production is turned on, it is relatively difficult to adjust process parameters.